Overview of cubic boron nitride cutting tool materials

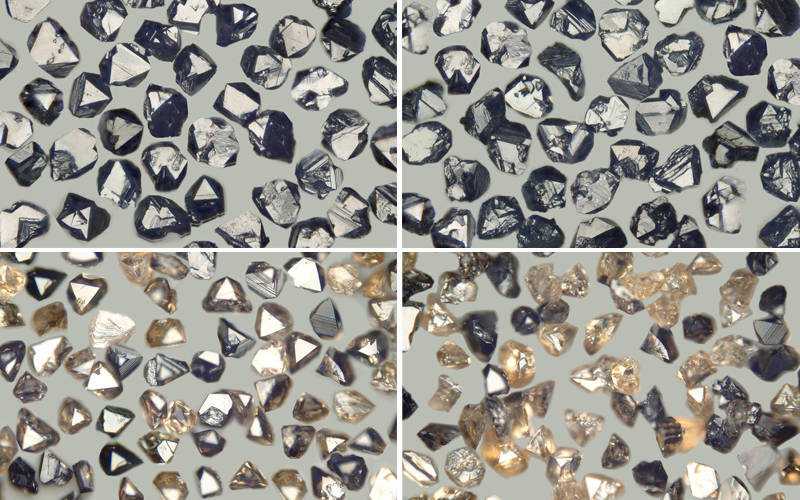

CBN cubic boron nitride blade definition

cubic boron nitride is the second hardest material known in nature. its hardness is second only to diamond. it is an ideal tool material for hard turning of ferrous metals.

20in the 1970s, people used cubic boron nitride powder materials and a small amount of binders to synthesize them under high temperature and pressure. CBN cubic boron nitride blades, due to their good processing performance, have gradually become one of the first choice tools for materials with high hardness and difficult to machine.

CBN cubic boron nitride blade performance characteristics

CBN the outstanding advantages of cubic boron nitride blades are high hardness and good red hardness, so they have characteristics that ordinary cutting tools do not have.

(1)high hardness and good wear resistance. CBN the hardness of cubic boron nitride blades is second only to diamond, and PCD the cutting tools are collectively called superhard cutting tools. CBN cubic boron nitride blades are suitable for processing high-hardness ferrous metal materials that can only be ground previously, and can obtain better surface quality.

(2)good thermal stability. CBN cubic boron nitride blades have a heat resistance of up to 1400 ~1500℃,the heat resistance is twice as high as that of diamond, and it is the best heat-resistant tool among all tools, so it can be used for high-speed turning.

(3)good chemical stability. CBN cubic boron nitride blades have high inertness and are comparable to iron-based materials at 1200 ~1300℃there will be no chemical reaction, and there will be no sharp wear during high-temperature cutting.

(4)good thermal conductivity. CBN cubic boron nitride inserts have good thermal conductivity, which is much higher than high-speed steel and cemented carbide. as the cutting speed increases, the thermal conductivity will also increase, which will help reduce the temperature of the cutting zone and reduce diffusion wear.

(5)low coefficient of friction. CBN the friction coefficient of cubic boron nitride blades is low and the cutting force generated during cutting is small, which can effectively improve the surface quality.

CBN cubic boron nitride blade types and models

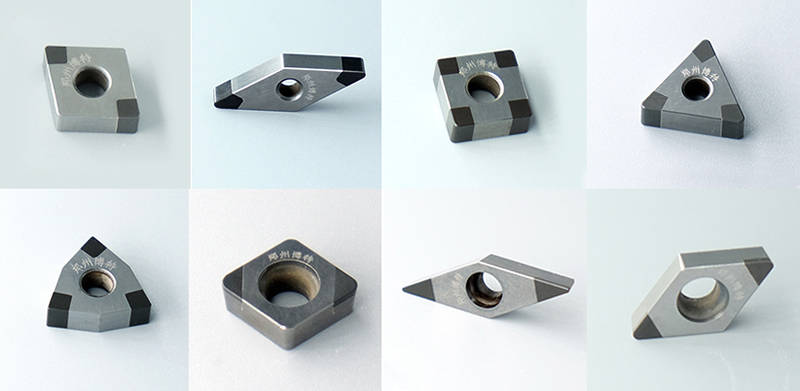

depending on the blade structure, bot CBN cubic boron nitride blades can be divided into solid polycrystalline cubic boron nitride blades and welded cubic boron nitride blades.

monolithic polycrystalline cubic boron nitride blade

the overall polycrystalline cubic boron nitride blade is made of sintered cubic boron nitride. it is a machine-clamped indexable blade with many cutting edges, high bending strength, and can withstand large depth of cut and high-speed cutting. common models include: SNGN、RNGN、RCGX、RCGV、CNGN、SCGN wait.

welding cubic boron nitride blades

welding cubic boron nitride blades, only the tip part is made of cubic boron nitride material, the middle matrix is made of carbide material, with a center hole positioning, it can replace the coated blade, suitable<2mm processing="" conditions.="" common="" models="" include:="" cnga="">

CBN cubic boron nitride blades can process materials

generally speaking, when turning metal workpieces, the hardness of the tool material used is more than 4 times greater than the hardness of the workpiece, which results in a cutting hardness greater than HRC45 becomes a problem when using the above metals, CBN cubic boron nitride blades solve just such problems.

(1)gray cast iron. it has low hardness, good shock absorption and wear resistance, and requires high wear resistance of the blade. CBN cubic boron nitride blades have strong wear resistance and can achieve high-speed turning of gray cast iron workpieces, improving processing efficiency.

(2)high hardness cast iron. such as high chromium cast iron, ductile iron, chilled cast iron, high nickel chromium cast iron, etc., use CBN cubic boron nitride inserts can be turned directly with large margins without severe wear or chipping.

CBN hard turning of cubic boron nitride inserts

(3)quenched hard steel. steel parts whose hardness becomes higher after quenching, general hardness >HRC50 above, can be used CBN hard turning of cubic boron nitride blades achieves the effect of turning instead of grinding. the machining allowance is less than 0.5 mm it is recommended to use welded cubic boron nitride blades with a machining allowance greater than 2 mm it is recommended to use solid cubic boron nitride blades.